Expanded sheet steel is a flexible material used in a variety of industries for various apps because of its toughness, durability, and flexibility. In the following paragraphs, We'll delve deep in the production process of expanded sheet steel, exploring the steps involved as well as the strategies utilized to build this special material.

Introduction to Expanded Sheet Metal

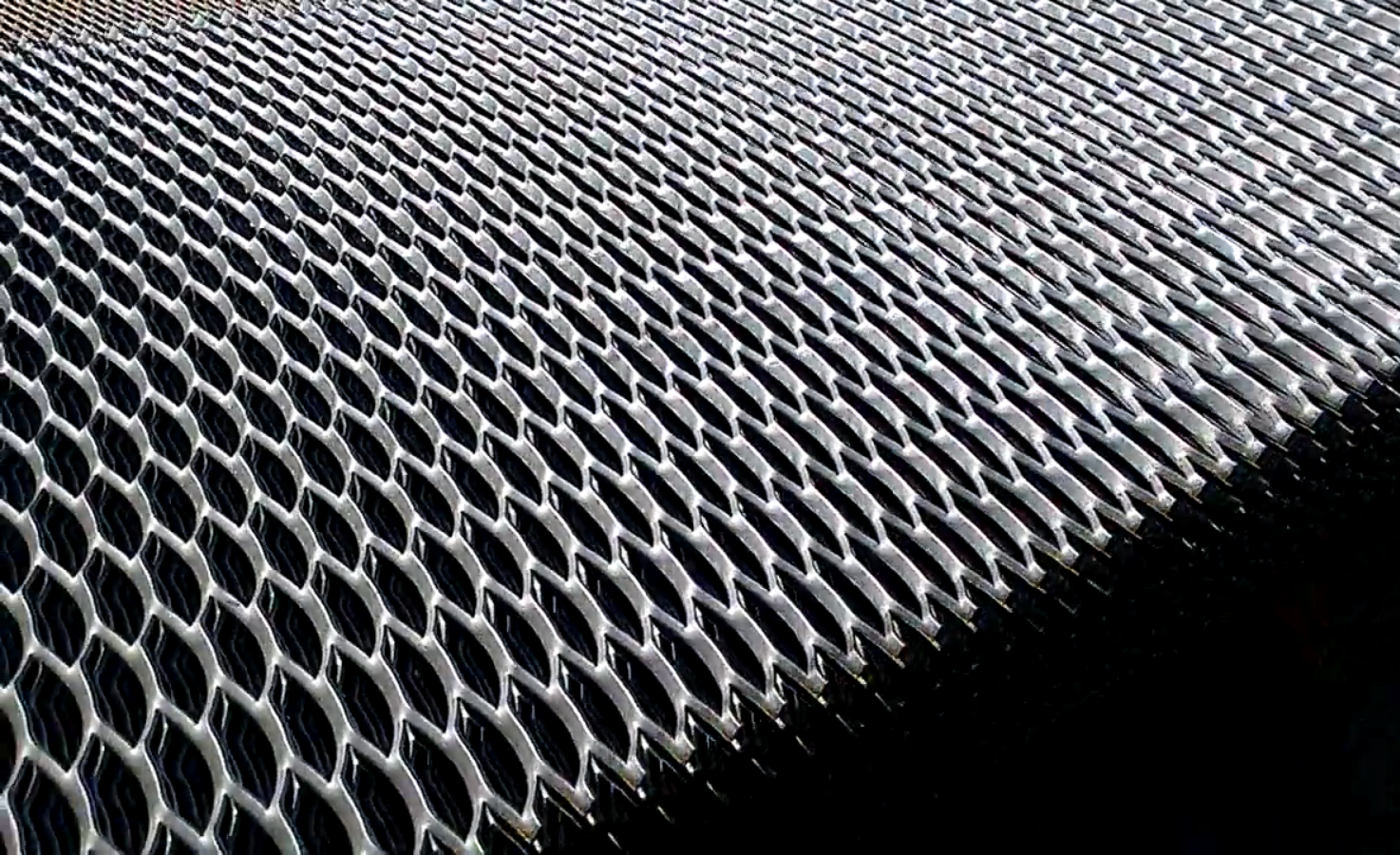

Expanded sheet steel is often a kind of metal sheet which has been processed by way of a number of chopping and stretching functions to produce a pattern of diamond-formed openings. This method ends in a material that is definitely much better plus more rigid than common sheet metallic when however preserving a light-weight and flexible mother nature.

What is Expanded Sheet Metallic?

Expanded sheet metallic is developed by slicing slits within a steel sheet then stretching it to kind diamond-shaped openings. This method raises the surface area region of the material, making it more powerful and more long lasting than common sheet metal.

Why Select Expanded Sheet Metallic?

Expanded sheet metallic offers numerous rewards above conventional sheet metallic, like elevated toughness, rigidity, and flexibility. It is also additional lightweight and value-efficient, making it a perfect choice for a wide range of applications.

The Production Process

The producing http://news-about-ferrous-metal-products-mmdh716.yousher.com/najefektivnisi-sposobi-vikoristanna-riznih-rozmiriv-lista-pvl-u-budinkovomu-gospodarstvi strategy of expanded sheet metallic includes numerous techniques which might be carefully executed to ensure the standard and consistency of the final item. Let's get a more in-depth have a look at Every phase of the procedure:

1. Material Selection

The initial step during the manufacturing method is choosing the appropriate content with the expanded sheet steel. Differing types of metals can be employed, together with steel, aluminum, stainless-steel, and copper, depending upon the desired Attributes of the final product.

2. Cutting

Once the fabric is picked, it is actually Slash into sheets of the specified dimensions making use of specialised slicing tools including shears or laser cutters. The sheets are then cleaned and ready for the following stage of the process.

3. Slitting

In this phase, slits are made within the steel sheets using a slitting machine or press. The slits are strategically put to create a unique pattern that may be expanded afterwards in the process.

4. Stretching

After the slitting course of action is full, the metallic sheets are fed into an growing device that stretches them in equally Instructions to create the diamond-shaped openings attribute of expanded sheet metallic. The level of stretching utilized establishes the scale and shape on the openings.

5. Flattening

Once the stretching process is completed, the expanded sheets are flattened using rollers or presses to get rid of any wrinkles or imperfections caused during growth. This stage makes sure that the sheets are sleek and uniform in thickness.

6. Reducing to Size

The final action in the manufacturing course of action consists of cutting the expanded sheets for their ultimate Proportions working with precision reducing tools. This makes sure that Just about every sheet meets the required technical specs for its intended application.

FAQs about Expanded Sheet Metal

Here are a few usually requested questions on expanded sheet metallic:

1. What exactly are some widespread programs of expanded sheet steel?

Expanded sheet metallic is Utilized in different industries for programs for instance fencing, grating, filters, screens, partitions, and decorative needs.

2. Is expanded sheet steel corrosion-resistant?

Yes, depending on the variety of fabric utilised (which include chrome steel or aluminum), expanded sheet steel is usually highly proof against corrosion, making it well suited for outdoor use.

3. Can expanded sheet metal be painted or coated?

Yes, expanded sheet metallic might be painted or coated with protective finishes to improve its visual appeal and longevity although supplying added resistance to corrosion.

4. How does expanded sheet steel Examine to perforated sheet steel?

Expanded sheet steel generally has greater openings than perforated sheet steel and gives better power and rigidity as a result of its exclusive manufacturing procedure.

5. What factors need to be considered When selecting expanded sheet metal for a certain application?

When deciding upon expanded sheet metallic for a particular application, variables which include product form, thickness, opening measurement, sample structure, end, and environmental conditions need to be taken under consideration.